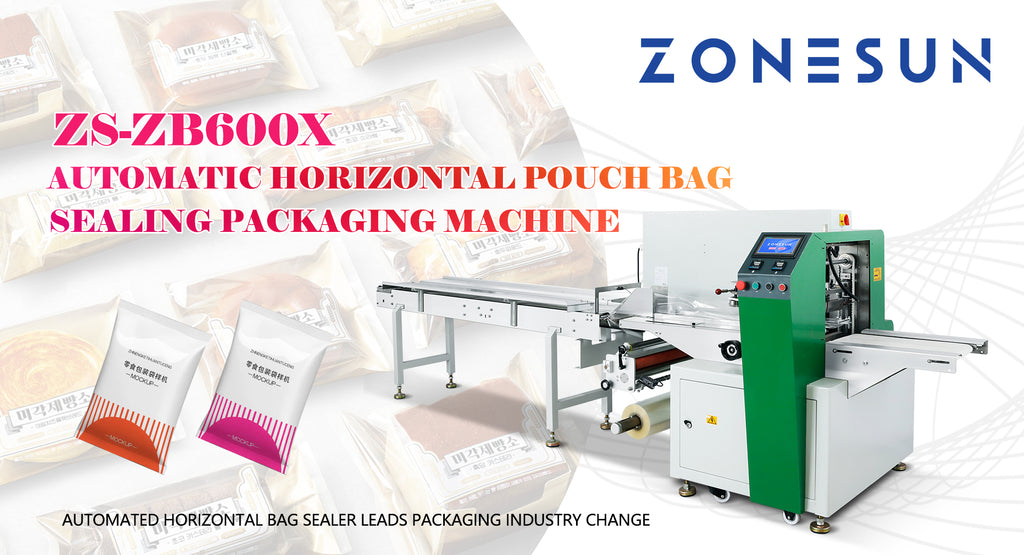

Automatic Horizontal Pouch Bag Sealing Packaging Machine

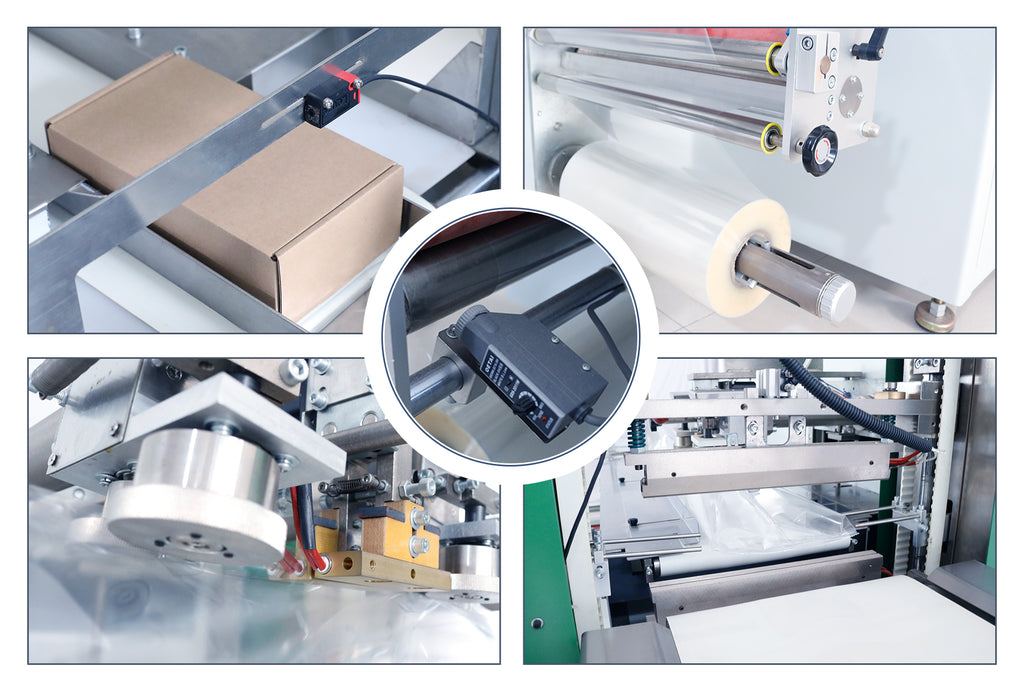

First and foremost, the ZS-ZB600X is highly productive. With advanced drive systems and precise positioning technology, this machine is capable of performing bag sealing tasks quickly and accurately. Whether it is a single-layer or multi-layer bag, the ZS-ZB600X can effortlessly handle various production requirements. By doing so, it effectively reduces labor costs while significantly improving production efficiency.

One of the remarkable features of the ZS-ZB600X is its wide applicability. This machine can accommodate different types of packaging materials, such as plastic, paper, and aluminum foil. This versatility allows companies to utilize various packaging options based on the specific needs of their products. Additionally, the ZS-ZB600X supports bags of different sizes and shapes, providing even greater flexibility for companies to quickly adjust their production scale and product offerings in response to market demand.

By incorporating the ZS-ZB600X into their production lines, companies can experience several benefits. Firstly, the machine's high productivity enables faster packaging processes, leading to increased output and shorter lead times. This, in turn, allows companies to meet customer demands more efficiently and effectively.

Moreover, the ZS-ZB600X's precise positioning technology ensures consistent and accurate bag sealing. This eliminates the risk of product leakage or contamination, providing a reliable packaging solution for companies across various industries, including food, pharmaceuticals, and consumer goods.

Furthermore, the ZS-ZB600X's ability to work with different packaging materials contributes to sustainability efforts. By accommodating plastic, paper, and aluminum foil, the machine allows companies to choose eco-friendly packaging options based on their environmental goals and market demands. This flexibility aligns with the growing consumer preference for sustainable packaging solutions and helps companies establish themselves as responsible and environmentally conscious brands.