ZONESUN ZS-SBMM1 Blow Molding Machine for Cosmetic Bottle Production

- Price

- $12,999.00

Pre-sale Support

👋

Have questions about ZONESUN?

Get in touch with us through the following channels:

Contact Details

E-mail: info@zonesunpack.com

Phone / WeChat / WhatsApp: +008618924567106

ZONESUN Official Website: www.zonesunpack.com

Company Information

Chinese Company:

Guangdong Shanghang Technology Co., Ltd.

Address:

No.8, Lane 1, East Dianbian Road, Nanyue, Shang An, Jinsha, Danzao Town, Nanhai District, Foshan City, Guangdong Province, China.

Postcode: 528223

Shipping Information

Goods will be sent out within 3-7 working days after payment of the order. Delivery times may vary due to order quantities or production schedules of the time, and are subject to order information.

In order to offering better service, we have operated with multiple shipping companies like Fedex, DHL, DUP, UPS, EMS etc. We ensure that you can choose the most suitable one for our online products.

- Most of them will be shipped by express shipping like Fedex or DHL, delivery time is 6-8 business days.

- Some small products will be sent by regular shipping, delivery time is 15-45 business days. (There is an instruction saying this product will be sent by regular shipping.) But if you need faster shipping, please contact us to upgrade shipping method. We are glad to help you.

- Some customers can not place their order since there is an error saying that we can not deliver the product to their countries. If you are in this situation, please contact us to confirm the price and shipping, we will help you place the order successfully. The shipping fee is hard to set up online, and in this situation, it is possible to spend less money to get this product, so it will be better if you can contact us.

- If you find the shipping fee is too expensive for you, please contact us, we are glad to help you find the best shipping method. For large machine, it will be better for you to contact us before placing the order, in this way we can confirm the price, delivery time and check if the machine is really suitable for your products.

Payment

You may find that we only support PayPal now, but we can offer other payment method like West Union, TT, Credit Card, WeChat Pay, Alipay. You will find the best one as your need. If you have any problems about payment, please send us message. Although some of them are not supported on online service now, we are trying our best to upgrade these.

Contact Support

We know some customers may need the product urgently and hope they can place the order as soon as possible. In this situation, we offer e-mail and online chat support to help our customers to know more things about our products and service.

Questions about the shipping information should be sent to us at: info@zonesunpack.com

Our Contact Information

ZONESUN Technology Co., LTD

E-Mail: info@zonesunpack.com

Phone / WeChat / WhatsApp: 0086 18924567106

Address: No.8, Lane1 East Dianbian Road, Nanyue, Shang An, Jinsha, Danzao Town, NanHai District, FoShan City, GuangDong Province, China.

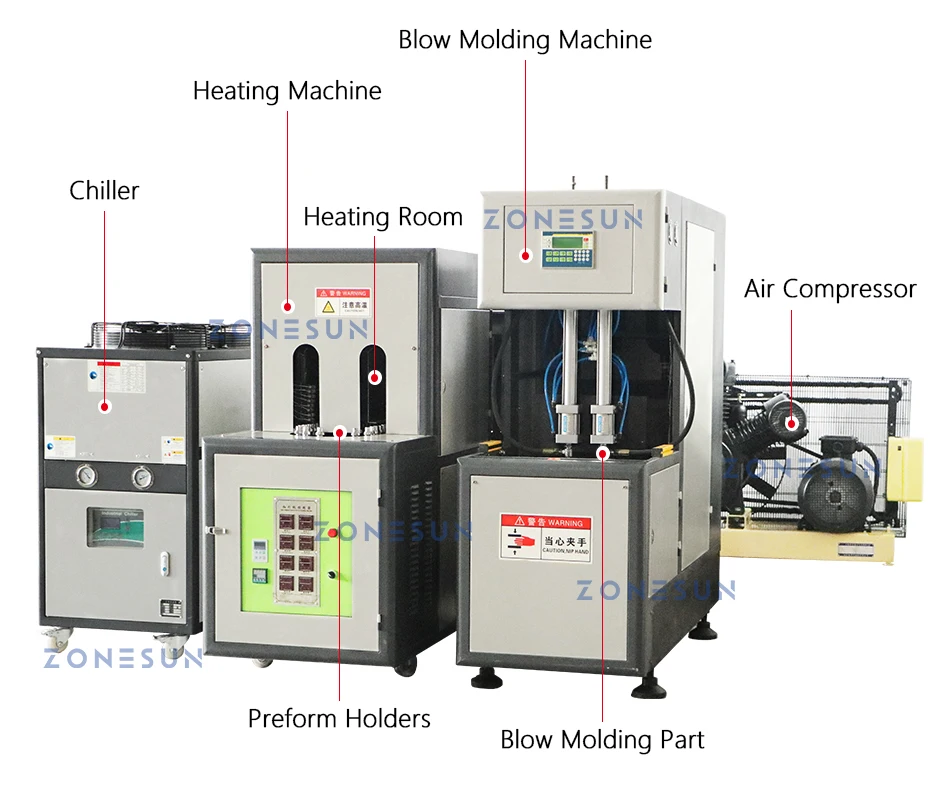

The ZS-SBMM1 blow molding machine offers a compact, high-performance solution for producing elegant cosmetic containers and other plastic packaging. With advanced infrared heating and rotary design, it delivers uniform bottle quality and surface finish. Built for reliable, scrap-free molding with easy maintenance, this system is ideal for small to mid-sized factories seeking premium packaging results.

FEATURES

- The machine provides fast molding performance without scrap or connecting lines on bottle bottom or side.

- Maximum uniformity of bottle weight, thickness and volume.

- Extremely smooth and elegant bottle surface is ideal for high-quality and high-price packaging.

- Infrared heating tubes combined with rotary design ensures extremely uniform heating for PET preforms, superior molding performance, and minimizes product defects.

- Full-time stabilized heating system. Heating temperature and speed are adjustable according to sizes and features of preforms.

- Consistent operation, minimal trouble and easy maintenance.

- Requires little floor space, suitable for small to middle size factories.

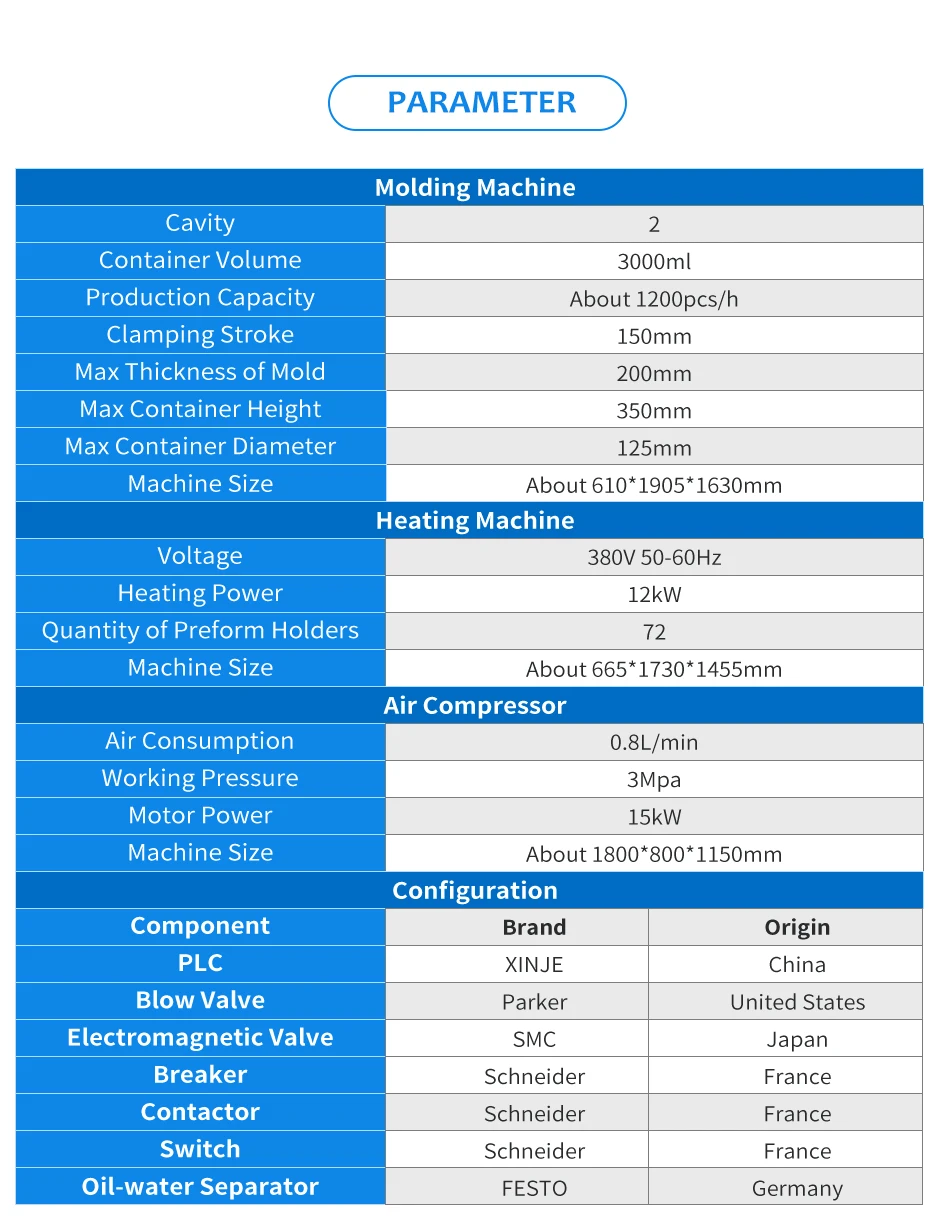

PARAMETER

|

Molding Machine |

||

|

Cavity |

2 |

|

|

Container |

3000ml |

|

|

Production Capacity |

About 1200pcs/h |

|

|

Clamping |

150mm |

|

|

Max Thickness of Mold |

200mm |

|

|

Max |

350mm |

|

|

Max Container Diameter |

125mm |

|

|

Machine |

About 610*1905*1630mm |

|

|

Heating Machine |

||

|

Voltage |

380V 50-60Hz |

|

|

Heating Power |

12kW |

|

|

Quantity of |

72 |

|

|

Machine Size |

About 665*1730*1455mm |

|

|

Air Compressor |

||

|

Air Consumption |

0.8L/min |

|

|

Working |

3Mpa |

|

|

Motor Power |

15kW |

|

|

Machine |

About 1800*800*1150mm |

|

|

Configuration |

||

|

Component |

Brand |

Origin |

|

PLC |

XINJE |

China |

|

Blow Valve |

Parker |

United States |

|

Electromagnetic Valve |

SMC |

Japan |

|

Breaker |

Schneider |

France |

|

Contactor |

Schneider |

France |

|

Switch |

Schneider |

France |

|

Oil-water Separator |

FESTO |

Germany |

HEATING

Infrared heating tubes combined with rotary design ensures extremely uniform heating for PET preforms, superior molding performance, and minimizes product defects.

BLOW MOLDING

The machine provides fast molding performance without scrap or connecting lines on the bottle bottom or side.